New circular construction methods emerging

The construction sector currently accounts for 25-30 % of all waste generated in the EU and the global construction market is expected to grow by 85 % by 2030. Applying circular economy in the construction industry requires a new systems thinking approach with an understanding of the building life cycle and construction value chain.

The construction industry is the largest consumer of raw materials

The combined impact of population growth, increased prosperity and effects of climate change is leading to an increased competition for natural resources. Today, construction and use of buildings accounts for almost half of all raw material consumption and energy consumption and for about one third of all water consumption in the EU. Circular economy is one of the most interesting concepts for a more sustainable development, a concept where business benefits go hand in hand with resource efficiency. According to the EU, circular economy is defined as an economy where the value of products, materials and resources is maintained in the economy as long as possible and waste generation is minimized. Circular economy can not be achieved by one single company, but requires collaboration between traditional and new actors in the supply chain in order for the cycle to be able to circulate efficiently.

Does the world get better?

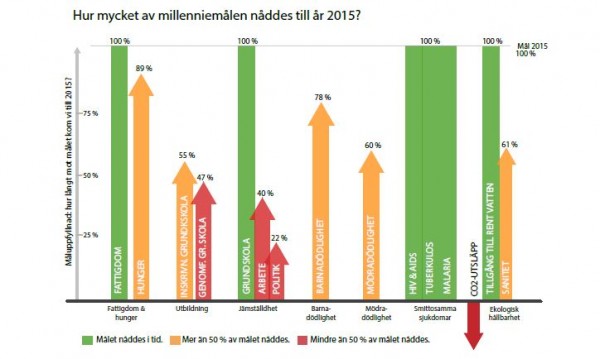

In the year 2000, the world's leaders agreed on eight important Millennium Development Goals to be achieved by the year 2015. In the report "Does the world get better?", published in Swedish by the United Nations Development Program UNDP, it is noted that some of the goals performed better than expected (Figure 1). The goal of a 50% reduction of people living in extreme poverty was achieved ahead of the 2015 deadline. The only goal that had a negative development was the goal of environmental sustainability and CO2-emissions. The new goals to be achieved by 2030 therefore have a much greater focus on environmental sustainability and climate change.

Figure 1. Graph showing how the world achieved the Millennium Development Goals in 2015. Source: UNDP, ”Blir världen bättre?”.

Circular economy

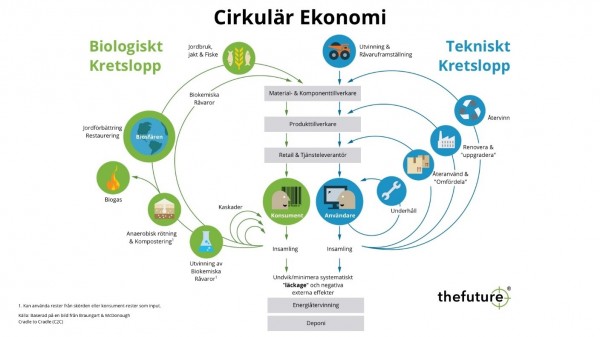

The circular economy aim is to maximize the use of renewable materials within biological systems, and to extend the life of non-renewable materials within technical systems (Figure 2). Building materials as a group are attributed to the technical cycle. In the case of processed, biological building materials (eg wood), their life cycle can be extended by designing the products for multiple reuse in the technical cycle before they are finally used for energy recovery or enters the biological cycle.

Figure 2. Illustration of a circular economy, divided into a biological and a technical cycle. Source: The figure with Swedish text is from thefuture. The original illustration from Braungart & McDonough, Cradle to Cradle (C2C).

The technical cycle

Products in the technical cycle should be designed for re-use, remanufacturing and recycling so that materials can circulate. Re-use means that the product is used several times without changes in design or material, unlike recycling where the product is destroyed and the materials are used for manufacturing new products. Remanufacturing means that a used product is being renovated to the same standard as a new product. In the technical cycle, smaller circles are preferred over larger circles, since smaller circles retains more value (e.g. maintenance is prioritized over recycling).

Design for Deconstruction

When it is time for a building to be demolished, many building components are still far from being worn out. The NCC report ”Design for Deconstruction – Kartläggning av byggnadselement” describes new opportunities for a more circular construction. Design for Deconstruction (DfD) is a method describing how to design products that can be more easily disassembled (Figure 3). DfD offers technical possibilities to re-use structural elements (such as beams, columns, walls, joists and roof trusses) and enables production of more flexible buildings that can be easily maintained, rebuilt and repaired. Changing the construction process to build according to DfD is a challenge that requires innovative thinking and new business models.

Figure 3. Examples of technical solutions according to Design for Deconstruction. Source: 3XN/GXN, ”Building a Circular Future”.

Prefabricated modular systems and digital production

Faaborg-Midtfyn Municipality in Denmark has started a project called "Modular systems in cultural heritage buildings" that demonstrates how to revitalise important cultural heritage buildings by using prefabricated modular systems and digital production. The municipality will, together with the Aarhus School of Architecture and with support from the Danish Transport, Construction and Housing Authority, renovate one of the buildings at Fabers Fabrikker in Ryslinge to four attractive apartments.

In September 2018, the EU project "Circular Economy - A Game Changer for the Wood Building Industry" at Novia University of Applied Sciences visited Fabers Fabrikker to learn more about the case (Figure 4). The building is renovated according to the "house in a house" principle, where the historical building fabric is preserved and a new core of prefabricated apartment modules are built inside. The modules are designed to fit into the old building with the help of 3D scanning. Not all square meters will be renovated, only four smaller apartments will be built inside one of the buildings in the industrial area. The apartment modules will be well insulated and heated for high comfort while the space between the modules and the building fabric will be unheated and can be used as inner court yards.

Several circular economy aspects can be met with modularization, such as improved energy efficiency and reduced material consumption. In addition, new types of service systems for maintenance and upgrades can also be make it easier and cheaper to maintain the modules. More information on this can be read in the report Modularisering för cirkulär ekonomi.

Figure 4. Fabers Fabrikker, a historic factory building that is being renovated using 3D scanning and prefabricated modular systems. Photos: Annika Glader.

Digital material passports

BAMB (Buildings as material banks) is an EU project that investigates how products and materials in buildings can be reused and recycled without losing value. The BAMB project has launched a Materials Passport Platform, a prototype for digital management of buildings as material banks. A material passport is a document that contains data on all materials in a product, which gives the product a value for re-use, remanufacturing and recycling. It is important to preserve the materials in a product as pure as possible so that they can be easily separated and recycled to equal or higher value. For example, it is much more difficult to recover material if they are nailed or glued together than if they are assembled with screws and bolts.

One of the pilot cases in the BAMB project is BRIC (Building reversible in conception), where student groups assemble and disassemble a sustainable, scalable and reversible building three times during a three-year period. Each disassembling is accompanied by a change in the function of the building. The work on assembling and disassembling the building can be followed on the BAMB website.

Article author:

Annika Glader

Project Manager

Novia University of Applied Sciences